4R Energy, a joint venture between Nissan and Sumitomo that focuses on EV battery reuse, will be the first group certified to the UL 1974 Standard for Evaluation for Repurposing Batteries. UL 1974 outlines how to sort and grade EV battery packs, modules, and cells, identifying state-of-health and determining viability for second-life use as storage…. Read more »

Search Results Found For: "battery reuse"

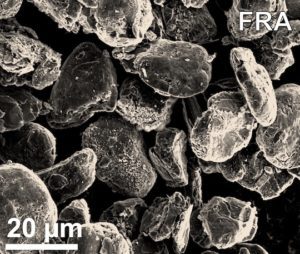

Rice University announces new process to revive lithium-battery anodes for reuse

Rice University scientists have reported what they believe to be a partial solution to the mounting disposal problem of worn-out lithium-ion batteries. It relies on a unique “flash” Joule heating process they have developed to produce graphene from waste. The lab of Rice chemist James Tour is said to have reconfigured the process to quickly… Read more »

Axion, Aceleron and Aspire launch battery recycling and reuse initiative

Circular economy and resource recovery specialists Axion, Aspire Engineering and Aceleron have launched an initiative to tackle the growing number of end-of-life EV batteries. They are currently providing a recovery service that begins with Aspire processing the batteries for remanufacturing, reuse and recycling. Next, Aceleron tests and repurposes the batteries. If the batteries cannot be reused, Axion will then… Read more »

Fraunhofer IPK develops technical standards for EU digital battery passport

The Fraunhofer Institute for Production Systems and Design Technology IPK, a research institute in Berlin, is participating with the Battery Pass Consortium to design and implement the technical standards of the EU’s digital battery passport. The passport will be required by the EU Batteries Act for new traction batteries, two-wheeled-vehicle batteries and industrial batteries with… Read more »

Projected EV battery recycling capacity outstrips expected supply

Afraid there won’t be enough recycling plants to recycle EV batteries when they start reaching end of life in large numbers? Well, the opposite might turn out to be the case. Encouraged by generous government incentives, companies have been investing heavily in battery plants. According to new research from technology intelligence firm ABI Research, companies… Read more »

Aqua Metals is building a more sustainable battery recycling ecosystem

Q&A with Aqua Metals execs Steve Cotton and David Regan Regardless of the claims made in Facebook memes, Li-ion batteries are eminently recyclable, and current recycling methods cause far less environmental damage than the well-documented depredations of the petroleum industry. However, as sustainability is central to the mission of the EV industry, we need to… Read more »

Altilium, Synetiq and LV= collaborate to facilitate EV battery recycling in the UK

UK-based clean technology group Altilium is collaborating with vehicle salvage and recycling specialist Synetiq to recycle the growing number of EV batteries from damaged cars. Synetiq processes thousands of cars each year, and currently has an inventory of damaged EVs at its UK facilities. The company has invested heavily in equipment to remove the batteries… Read more »

Quality management and the future of battery manufacturing

Sponsored by Siemens. As the energy transition and electrification of mobility drive the explosive demand for batteries, Christophe Mazeaud, director of Battery Industry Solution, Siemens Digital Industries Software, discusses the key role that a holistic quality program plays in scaling and stabilizing battery production. What we are seeing across the battery manufacturing landscape is an… Read more »

Dynexus uses pattern recognition to make a powerful battery health measurement technique even better

Measuring battery health and safety continuously is an important challenge—lithium-ion batteries can experience several challenges over their lifetimes such as unintended capacity loss, short circuits and thermal runaway. In 2011, Idaho National Laboratory researchers developed a new technology for measuring battery health and safety. By sending multiple waves of electrical current simultaneously through a battery,… Read more »

Smartville unveils battery energy storage system using retired EV batteries

US-based EV battery recycler Smartville has introduced a new battery energy storage system (BESS) using retired EV batteries. (See the feature article in our July-September issue.) The Smartville 360 BESS combines repurposed automotive lithium-ion battery packs from multiple automotive makes and models that meet Smartville’s specifications and proprietary safety and life-cycle optimization controls. The Smartville… Read more »