The Baden-Württemberg Ministry of Economics will invest €1 million to fund the AgiloDrive research project at Karlsruhe Institute of Technology (KIT). The project is aimed at developing a novel, agile electric motor production system based on modular product- and production-specific technologies. Professor Jürgen Fleischer, Head of the wbk Institute of Production Science, stated, “In this… Read more »

Search Results Found For: ""Karlsruhe Institute of Technology""

Karlsruhe Institute of Technology establishes hub to help ICE tech companies transition to EVs

The Karlsruhe Institute of Technology (KIT) in Germany has established an organization that aims to teach companies experienced in manufacturing combustion engines how to transition their skills to EV technologies. The Transformation Hub Electric Mobility, which will target small to medium-sized companies, has been funded with €2.6 million from the German state of Baden-Württemberg. The… Read more »

Study finds recovering materials instead of shredding improves battery recycling

Karlsruhe Institute of Technology (KIT) researchers and industry partners including PowerCo, Umicore, Weber Ultrasonics and Siemens are working together to improve spent battery recycling by recovering active components while maintaining functionality. The consumption of energy and chemicals in current recycling processes is high. The new approaches are based on the direct recycling of active materials… Read more »

Mercedes outlines battery recycling strategy, will open recycling plant in Germany in 2023

Mercedes-Benz has unveiled plans to expand its global battery recycling strategy. The automaker will build its own battery recycling plant in Kuppenheim, Germany, and plans to enlist partners for battery recycling in China and the US. “Mercedes-Benz is pursuing a maximum circular economy for all raw materials used,” said Board Member Jörg Burzer. “Sustainable battery… Read more »

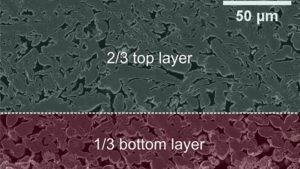

KIT researchers’ two-layer electrodes are simultaneously coated and dried

Researchers at the Karlsruhe Institute of Technology (KIT) have developed and tested a new concept for simultaneous coating and drying of two-layered electrodes. Drying times can be reduced to less than 20 seconds—one half to one third of the usual production time—without capacity losses. The institute continues to focus its research on coating and subsequent… Read more »

Researchers claim their graphene “SuperBattery” achieves a 15-second charging time

Skeleton Technologies and the Karlsruhe Institute of Technology (KIT) say they have developed a graphene-based battery with a 15-second charging time, as well as charging cycles counted in the hundreds of thousands. The so-called SuperBattery’s key component is Skeleton’s patented Curved Graphene carbon material, which enables the high power and long lifetime of ultracapacitors to… Read more »

Accelerated electrode drying could reduce battery production cost

A new EPIC project coordinated by Karlsruhe Institute of Technology (KIT) is aimed at accelerating the drying of electrodes for lithium-ion batteries, increasing the energy efficiency of this process and reducing production cost. KIT says innovative electrode drying management can reduce the cost of battery production and improve environmental performance. The quality of Li-ion battery… Read more »

New anode material could lead to safer batteries with long cycle life

Researchers at the Karlsruhe Institute of Technology (KIT) and Jilin University have investigated a promising anode material for future high-performance batteries: lithium lanthanum titanate with a perovskite crystal structure (LLTO). As the team reported in Nature Communications, LLTO can improve battery energy density, power density, charging rate, safety and cycle life without requiring a particle… Read more »

BMW launches Bidirectional Charging Management research project

A consortium of companies led by the BMW Group has launched the Bidirectional Charging Management (BCM) research project to develop backfeeding power technology, which will allow vehicles to transfer energy back into the power grid or customers’ homes when plugged into a compatible charging station or wallbox. The goal is to allow EVs to operate… Read more »

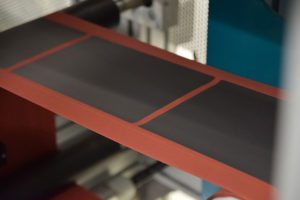

New coating process allows faster production of battery electrodes

Researchers at Germany’s prestigious Karlsruhe Institute of Technology (KIT) have created a new coating process that produces electrodes for lithium-ion batteries at record speed. The researchers say the new process also improves the quality of electrodes and reduces production costs. When manufacturing battery electrodes, a thin paste of electrode material is applied to a copper… Read more »