Researchers at Argonne National Laboratory are using a new imaging technique to learn more about the process that causes lithium-ion batteries to degrade over time.

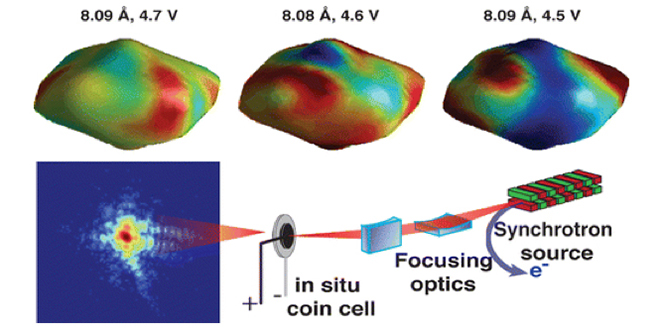

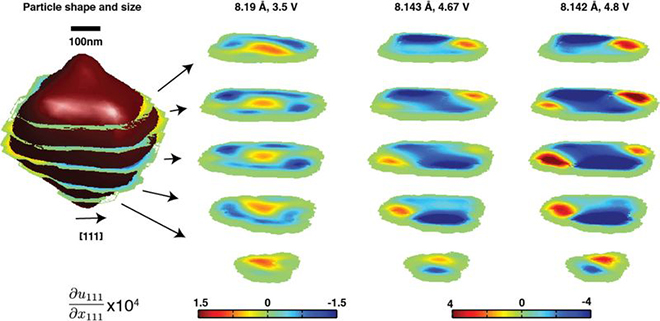

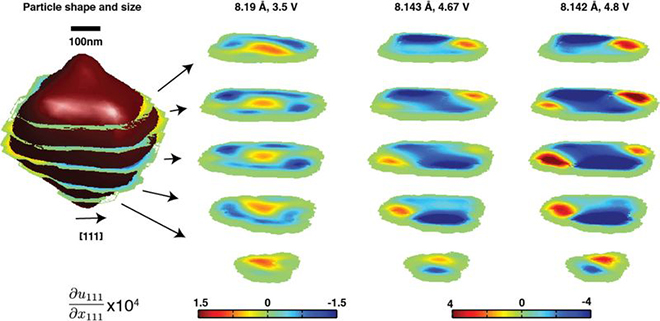

Using coherent X-ray diffractive imaging at the DOE’s Advanced Photon Source facility, a team of researchers mapped the three-dimensional strain in individual nanoparticles within the electrodes of operating batteries. In a paper published in Nano Letters, the team reported evidence that the history of charge cycles alters the patterns of strain in single particles of the electrode material.

Lithium ions strain the material as they shuttle between electrodes and can even alter its structure, which leads to defects. Designs for more resilient electrodes require a fundamental understanding of the interactions between ions and electrodes. But until now scientists have been unable to sufficiently characterize single nanoparticle behavior in batteries under real operating conditions.

“Central to degradation mechanisms in nanostructured electrodes are the nanomechanics of lithium ions, which remain insufficiently characterized at the single particle level under operando conditions,” write the researchers. “In particular, nano-structured spinel materials such as disordered LiNi0.5Mn1.5O4 (LNMO) are appealing as high-voltage, high-capacity, environmentally friendly and low-cost cathodes. However, capacity loss due to degradation is limiting its current use. Important degradation processes, including active material cracking, disconnection, and impedance increase can be understood in terms of strain evolution at the single particle level. Strain needs to be imagined in situ under operando conditions in order to provide insight into real processes and mechanisms.”

SEE ALSO: New study: Rapid charging doesn’t damage lithium-ion batteries as much as thought

“Bragg Coherent Diffraction Imaging (Bragg-CDI) is a technique that…can pick out single nanocrystals based on their crystal structure, and map out the evolution of strain inside the nanostructure as the whole battery is cycled,” said paper co-author Ross Harder.

Source: Argonne National Laboratory via Green Car Congress

Images courtesy of ACS, Ulvestad et al