Ultrasonic welding is one of many high-tech manufacturing processes that GM uses to produce its EVs, including the Chevy Volt and the new Cadillac ELR electric luxury coupe.

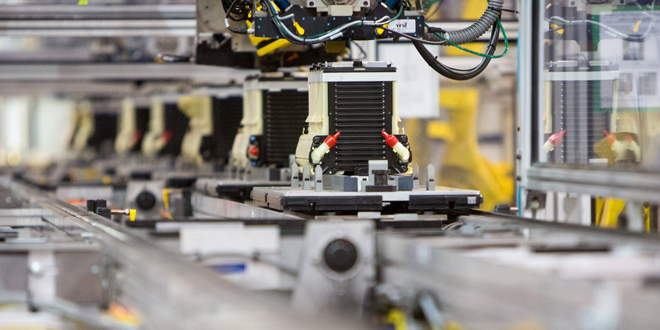

The technique employs a pair of tools called an anvil and horn to apply rapid mechanical vibrations to the battery’s copper and aluminum electrodes. This creates heat through friction, resulting in a weld that does not require melting-point temperatures. An integrated camera system shoots a reference image of the weld area, and the system monitors dozens of signal processing features during each weld.

Ultrasonic welding’s key advantage is highly consistent quality, which is extremely important for EV batteries. The process also offers short cycle times, low capital costs and manufacturing flexibility. Each ELR battery has almost 200 ultrasonic welds.

“Ultrasonic welding is a far superior joining technology in applications where it can be deployed,” said Jay Baron, CEO of the Center for Automotive Research. “Cadillac’s innovative process will produce batteries with superior quality compared with traditional methods – and do it more efficiently. This is one example of technology development that is becoming pervasive in today’s world class vehicles.”

The ELR’s 435-pound T-shaped battery pack is assembled at GM’s Brownstown Battery Assembly plant near Detroit, then shipped to Detroit-Hamtramck to be inserted into a new ELR.

Source: GM