As BMW prepares to bring its new i3 to market in 2014, expectations are running high. The upscale city car fills a vacant niche in the market, and it embodies all the advantages of a pure EV. Equally important, the company seems committed to making the i3 a success in the marketplace, rather than taking the “launch it and forget it” route that some other EV-makers have.

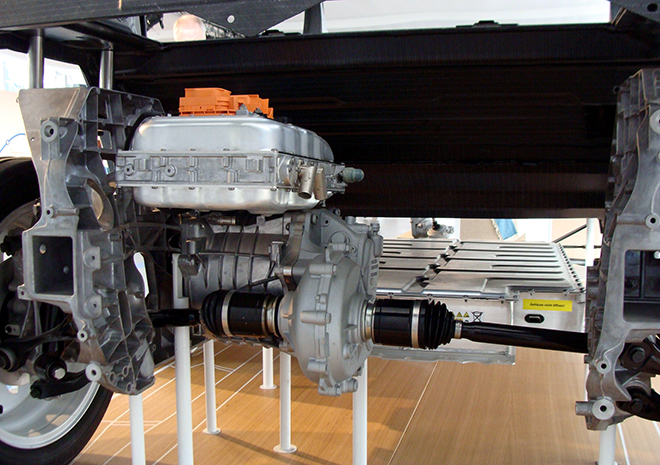

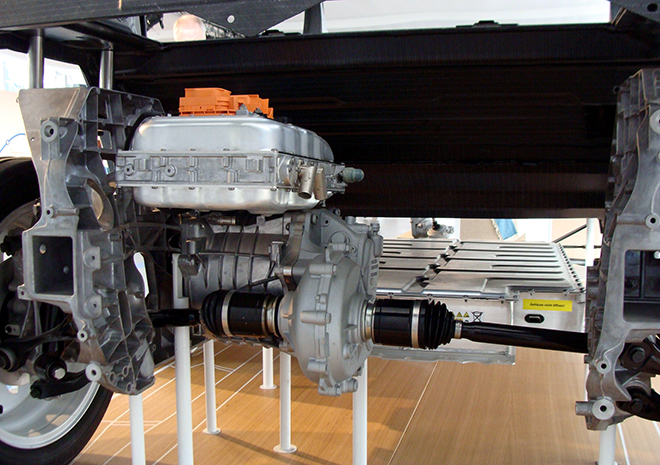

One sign of this is the fact that BMW has been systematically building its corporate EV expertise. Incorporating the lessons learned from the Mini E and ActiveE pilots, the company opted to develop almost all of the i3’s powertrain in-house, rather than outsourcing it. The battery cells come from Samsung, but BMW engineers designed all the battery packaging and controller electronics, as well as the electric motor.

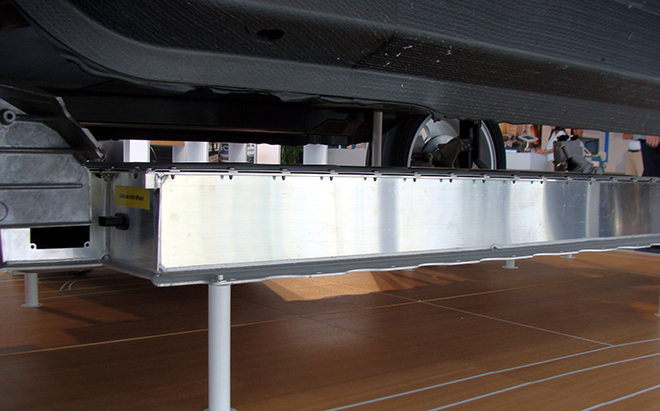

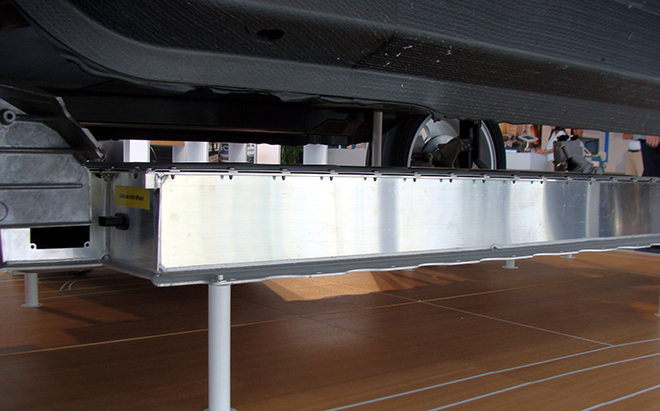

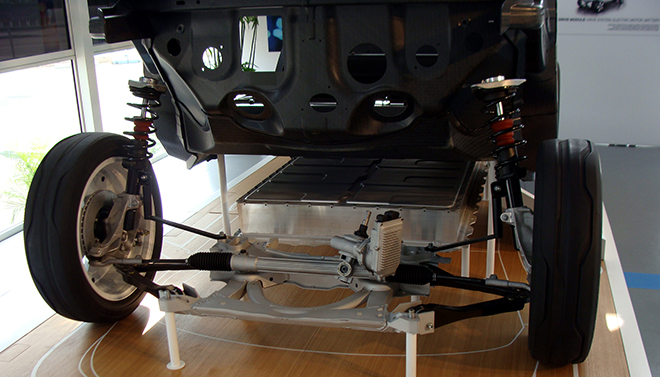

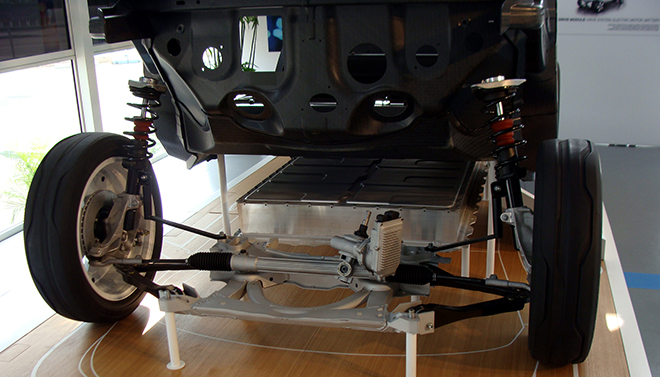

The flat battery pack, composed of 96 large-format automotive cells in 8 modules of 12, is housed at the bottom of the vehicle (in what BMW calls the drive cell), in such a way as to afford 50/50 weight distribution. This is one of the advantages of a purpose-built EV – putting the battery pack at the bottom greatly improves handling, and offers loads of interior space. Tesla tends to get the glory for coming up with this concept, but in fact it’s an idea that would occur to anyone who designs an EV “from the ground up.”

The i3’s battery is not designed for a Tesla-style quick change, but it can be swapped out in the repair shop within a couple of hours, which could prove to be a handy feature in the future, allowing an owner to replace an aging battery, or upgrade to a new and improved model.

The i3 uses AC refrigerant to cool the pack, electric mats for heating and can precondition it for hot or cold conditions while the car is plugged into the grid.

Designing an EV battery involves a multifaceted trade-off among size, weight, cost and vehicle range. BMW’s engineers chose not to design the i3 battery for maximum range, but rather to right-size it for a range that should be adequate for most city drivers. This allowed them to keep the cost and the size of the pack down, part of the reason the i3 offers generous interior space in such a small overall package.

“With the Mini E and the ActiveE, we did extensive research with folks who were driving the vehicles day in and day out, and we found that an 80-90 mile range was sufficient for most of what people needed the car to do,” BMW’s Dave Buchko told Charged. “Rather than trying to see how far we could stretch the range, we decided to use that as the constant, so if we lightened the vehicle, we could reduce the size of the battery pack. That’s one of the reasons why the i3 uses largely carbon fiber-reinforced plastic (CFRP) for the body shell. CFRP is comparatively expensive, but the way we’re doing it is inexpensive as carbon fiber goes. The offset is that by making the vehicle quite a bit lighter – the i3 is about 1,200 pounds lighter than the ActiveE – we could reduce the size of the battery from 32 kWh to 22 kWh. Reducing the size of the battery lowers the cost of the vehicle overall, so we offset some of the cost that we incur with the carbon fiber, and that’s why we can get to a price range of $41,000.”

A single glance makes it plain that the i3 is a new departure for BMW. It’s not a sedan, but a practical multipurpose car, albeit one with plenty of style. A variety of surfaces greet the eye. Most of the body panels are thermoplastic, but part of the roof is glass and part is carbon fiber – the carbon fiber frame is also visible around the door sills. The front fascia is a soft plastic that’s designed to spring back into shape after minor collisions – one of many practical features for urban drivers.

Inside there’s a variety of fabrics – most of them recycled or made from sustainable fibers – and a warm expanse of wood around the glove box. The controls are simple and intuitive, with the usual array of electronic gadgetry controlled via an LCD screen and a large navigational knob.

The one-pedal driving style is practical and fun once you get used to it. As soon as you lift your foot, the regenerative braking kicks in, slowing the i3 down. With a little practice, you’ll find that you seldom need to touch the brake. When you hit the go pedal however, this little car really scoots – it accelerates up the steepest hills with ease, and it leaps from a standstill to speed in the agile way that only an EV can do. Steering is effortless, and cornering is rock solid.

I drove the i3 on a course through Los Angeles that was cleverly designed to offer a little bit of everything: winding mountain roads, straight open stretches, stop-and-go city traffic and freeway gridlock. A wrong turn onto the Santa Monica pier even gave me a chance to evaluate the i3’s impressive turning radius under stress (and the watchful eye of a cop). This versatile vehicle handily passed every test. The coach doors and non-existent B-pillar make the passenger compartment feel spacious, and there’s even a respectable amount of cargo space, unimpeded by weird shapes or protrusions (a pet peeve of mine with most EVs).

Images by BMW and Charles Morris

Source: BMW