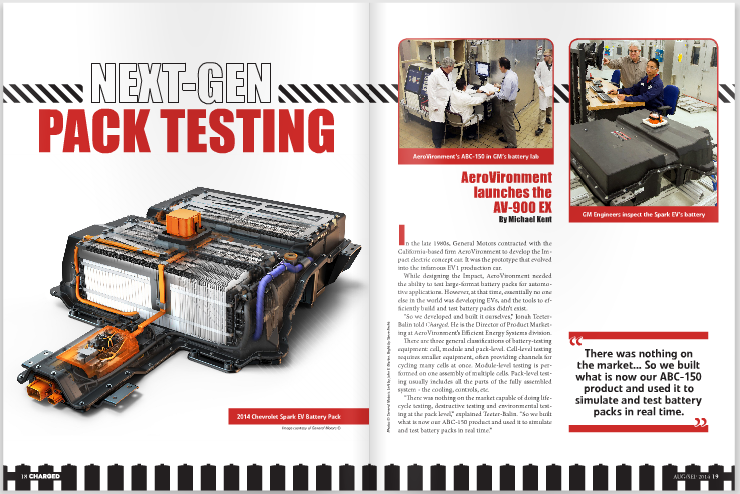

In the late 1980s, General Motors contracted with the California-based firm AeroVironment to develop the Impact electric concept car. It was the prototype that evolved into the infamous EV1 production car.

While designing the Impact, AeroVironment needed the ability to test large-format battery packs for automotive applications. However, at that time, essentially no one else in the world was developing EVs, and the tools to efficiently build and test battery packs didn’t exist.

“So we developed and built it ourselves,” Jonah Teeter-Balin told Charged. He is the Director of Product Marketing at AeroVironment’s Efficient Energy Systems division.

There are three general classifications of battery-testing equipment: cell, module and pack-level. Cell-level testing requires smaller equipment, often providing channels for cycling many cells at once. Module-level testing is performed on one assembly of multiple cells. Pack-level testing usually includes all the parts of the fully assembled system – the cooling, controls, etc.

“There was nothing on the market capable of doing life-cycle testing, destructive testing and environmental testing at the pack level,” explained Teeter-Balin. “So we built what is now our ABC-150 product and used it to simulate and test battery packs in real time.”

AeroVironment then began to sell its ABC-150, which provides power up to 125 kW, to battery test labs and other automotive companies. As the market grew, its customers came back asking for a product to conduct more sophisticated testing and to test bigger batteries. So, the company designed the AV-900, which is capable of providing testing power up to 250 kW.

Developed in the mid- to late-1990s, the AV-900 “was enough to do all the tests that the car companies and the test labs were asking for,” Teeter-Balin told us. “But now with all the new technologies – the new chemistries and other applications outside of EVs – the requirements for testing have become substantially more involved.”

To meet the new demands of a battery-powered-everything world, AeroVironment worked closely with customers to solicit a lot of feedback, and has announced its next-generation pack tester: the AV-900 EX.

Parallel potential

The new and improved product is an extension of the benchmark AV-900, with a lot of improvements in key areas. One unit by itself still delivers a maximum of 250 kW, but the company has built in the capability to run up to four units in parallel for 1 MW of power.

At the center of the upgrade is a switch from analog to digital controls, which led to efficiency increases across the board and many new feature possibilities. “This system has improved accuracy on the voltage and current, and thus the power side,” said Teeter-Balin. “Both the testing and the reporting of results are more accurate. We’ve improved the performance and speed of the system, quite substantially actually. So, now you can do testing a lot faster, and the signal responses are a lot better. We also added Ethernet communications so that customers can quickly send signals from a remote PC. And if they’re doing dynamic testing with a closed-loop test protocol, they’re able to do a lot more, a lot faster.”

Error detection, less down time

With new digital controls, the AV-900 EX is able to protect itself against issues that can pop up during testing and cause costly downtime. Over the years, AeroVironment found that customers were really aggressive, and were using the systems to experiment with a lot of new tests. The company says that it wanted to continue to enable users to push the limits, in ways that could not even be foreseen, and without as much risk to the system.

“Let’s say something changes during the test,” Teeter-Balin explains. “Instead of just shutting off completely, the system will say, ‘OK, I’ll ramp down slightly on power so that the system is protected, but keep other tests running.’ This is based on feedback from our customers who said, ‘We’re trying a lot of new stuff. It would be helpful if the system was robust enough to protect against the crazy new things that we’re trying.’”

One example of a downtime-causing error is grid fluctuations. AeroVironment has found that grid power and building power are not always clean, particularly in some international markets, and that can interrupt testing procedures. The AV-900 EX has new safeguards that are activated if the grid power fluctuates substantially, so there is no impact on testing at the system level.

Also, within the pack or module test itself, users can set soft limits. If a variable exceeds its limit on the battery side, the technicians are notified and can stop the tests to adjust the settings accordingly.

Error reporting and soft limits have always been a part of AeroVironment’s testing products, but with new digital controls, the AV-900 EX has improved that feature set substantially. Digital controls let users get to the cause of an error much more quickly, to get the test back up and running.

“Customers wanted much better feedback on the error side. It is all about efficiency for them,” said Teeter-Balin. “They want to get the maximum out of these systems, and anything that can help get them up and running quicker after something goes wrong, that’s a huge win for customers. They spend a lot of time monitoring the equipment to make sure that they are using these assets to maximize their testing throughput. When an error does occur, there’s a new LCD touchscreen display that tells you exactly where your input voltage has dipped or your current is exceeding limits, for example, with no need to root through a manual.”

There are standardized tests that will not be impacted much by the AV-900 EX’s new features. But many others, like destructive tests and life-cycle tests, can now be performed much faster. “We’re enabling our customers to do more types of testing, and faster if they want to,” said Teeter-Balin. “More testing in the same amount of time.”

Eyeing other markets

AeroVironment announced the new AV-900 EX in September, and is ready to start shipping in January. The company thinks this product will appeal to many new markets. One of the main reasons for the equipment upgrade was the feedback that AeroVironment has received from its other partners outside of the automotive world. A big part of its business is in military hardware, and those customers are beginning to look at new battery applications for heavy military use.

With a 1 MW maximum power rating, four AV-900 EXs in parallel are within the range of some stationary energy-storage applications – another fast-growing new market segment. The new unit even has a mode that can test solar panels under different light conditions: diffused, direct, angled, hot/cold, etc.

Also, there are heavy transportation sectors – ships, trains, trucks and planes – that are using more and more electric and hybrid systems. “They can all benefit from the enhanced performance of this product,” said Teeter-Balin. “We now feel that we can go after these markets that have very advanced batteries, very high discharge rates and much bigger power than a passenger automobile.”

This article originally appeared in Charged Issue 15 – August/September 2014