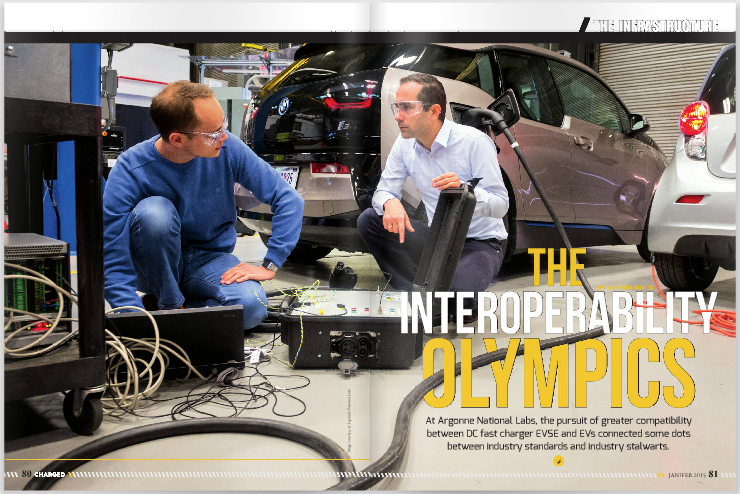

At Argonne National Labs, the pursuit of greater compatibility between DC fast charger EVSE and EVs connected some dots between industry standards and industry stalwarts.

America’s first national lab, Argonne National Laboratory (ANL), has always been steeped in the purpose of discovering and developing sustainable energy sources for promoting national security and prosperity. While the United States fought World War II on two fronts in 1942, Enrico Fermi’s work with the Manhattan Project spawned the precursor to ANL in an inner-city Chicago facility to create the world’s first self-sustaining nuclear reaction. Soon after, the laboratory was moved to a safer location 25 miles outside of Chicago and named Argonne after the forest surrounding it. Then in 1946 the post-war Atomic Energy Commission designated Argonne as the first national laboratory, tasked with developing the country’s peaceful pursuit of nuclear electricity. It was at Argonne-West in Idaho in 1951 that the world’s first nuclear-generated electricity brought a modest string of four light bulbs to illumination.

Now, more than 60 years later, ANL boasts 15 research divisions, 12 centers and 5 national scientific user facilities that host 3,400 full-time employees and more than 6,500 facility users. Its budget last year was $760 million, and it is only one of the 17 national laboratories overseen by the Department of Energy (DOE).

Standard setter

Argonne approaches its mission of finding scientific and engineering solutions to sustainable energy, a healthy environment and national security from many angles. Its facilities include a Center for Nanoscale Materials, supercomputers, a particle accelerator for studying the nucleic phenomena of atoms and many operations in the area of electric mobility. Argonne’s Transportation Technology R&D Center models and simulates advanced electric powertrains, engines, batteries and biofuels. ANL’s Joint Center for Energy Storage Research and Advanced Battery Materials Synthesis and Manufacturing R&D Program work on making the smart grid – including seamless interaction with plug-in cars and renewable energy sources – a reality.

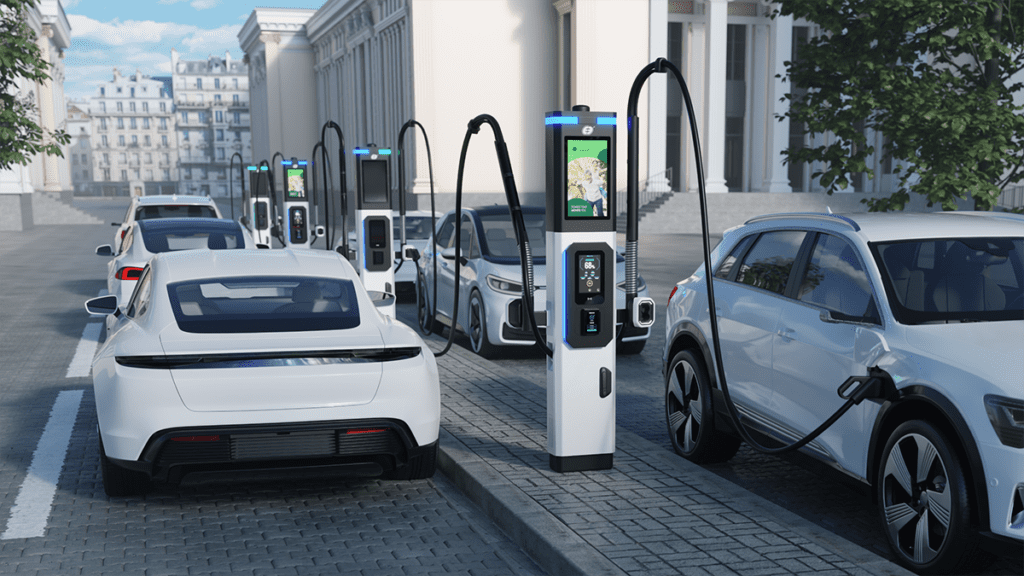

However, the lab doesn’t put the cart before the horse. In addition to all of its forward-thinking research, ANL participates very much in the here and now of vehicle electrification. The envisioned smart grid will need widespread fast charging for electric vehicles, as well as fast charging infrastructure that works regardless of the EV’s make and model, just as any brand of toaster you buy in America will plug into your kitchen outlets. To that end, ANL works on the interoperability of EVSE and EVs. Lab personnel often assist with the development of standards that govern such interoperability.

“We’re very much involved with the drafting of these standards codes, therefore helping develop these harmonized communication protocols that enable these markets to thrive,” said Glenn Keller, Senior Project Management Specialist at Argonne’s EV Smart Grid Interoperability Center.

The most recent DC Fast Charging standard that’s growing in adoption, SAE J1772 Combo – aka Combined Charging System (CCS) or just SAE Combo – combines AC charging and DC Fast Charging on one plug. Many North American and German automakers have adopted CCS, including the Volkswagen Group, which in January said that all its future plug-in vehicles will support DC Fast Charging with CCS. The Combo standard is just over two years old. “It was natural that we’d be called in to try to help out with that standard and mature that standard,” Keller said.

A fair of the state

Part of that maturation process involves the updating of other communication protocol standards that work with SAE J1772 to include DC Fast Charging for the CCS standard. So as part of that effort, the Interoperability Center held a “Testival” last November 13-14 at ANL to pair up as many DC Fast Charging stations and charger emulators with as many PEVs or vehicle emulators as possible to test their interoperability. The event prompted a greater response than expected, drawing more than 30 EVSE manufacturers and automotive OEMs from at least eight countries.

“The whole point to the event was the CCS communication controller testing,” said Jason Harper, Electrical Engineer at the Interoperability Center. “It was only going to be communications controllers to begin with, but we opened that up to actual plug-in electric vehicles, as well as DC fast chargers. We assumed there would be maybe a couple of vendors bringing small little boards, but it blossomed into this international event. I think we had every production vehicle that has a CCS inlet on it, and we had 6 or 7 fast chargers. Companies actually shipped their real fast chargers here to participate, and over 15 companies had communication controllers and brought boards.”

Like all of the Interoperability Center’s EV work, the Testival was funded by the DOE’s Office of Energy Efficiency & Renewable Energy. The event included DC Fast Charging CCS systems from IES/Bosch, Siemens, BTCP and others, as well as VW and Toyota plug-in vehicles and a BMW i3 and Chevy Spark EV, which were already at Argonne. All the equipment and controller boards were tested in a “round-robin” fashion, where each fast charger was paired with each vehicle, and each electric vehicle communication controller (EVCC) was paired with each supply equipment communication controller (SECC).

The CCS system covers three fast-charging standards: ISO/IEC 15118, DIN 70121 and SAE J2847/2. “ISO/IEC 15118 is a global standard, but the majority who follow it are European – it’s actually the digital communication messages for both DC and AC charging,” Harper said. “But a lot of the automotive OEMs didn’t want to wait for that to be published; they wanted to get started on DC Fast Charging, so DIN created DIN 70121, which is the DC messaging portion of the 15118 standard. Then SAE came along wanting to make it their own, so it harmonized with DIN70121, but uses the number J2847/2.”

It’s the little things

Harper said that they didn’t find any examples of incompatibility between one company that followed the ISO or DIN spec and another company that followed the SAE spec. “It was quite surprising that we didn’t find any totally un-interoperable pairings,” Harper said. “They’re very complicated standards – like 200-page documents that cover everything, so implementations can vary greatly. I assumed that a lot of these people coming in would plug in or connect their boards, and they would not work at all. That’s not to say that we had 100% interoperability, but for the most part, every pairing set up a communication session and charged if there was an actual vehicle, or at least went through the entire communication session. There were a few hiccups here and there, but with their developers in attendance, they could change their code in real time, recompile and test again.”

There was one non-production vehicle that had intermittent problems with initializing a session when plugged in. “They were at best at the prototype stage,” Harper said. “That’s why they came, because they didn’t have anything to test with.”

Other problems that the Testival helped to expose had to do with ambiguities within the CCS specifications. For example, before any high voltage exists at the CCS connector, the vehicle must lock the connector to its inlet. However, the spec didn’t say the connector couldn’t lock the instant it plugs in, which means that if a customer’s credit card wasn’t authorized or some other mishap meant a charging session wasn’t started, the customer could be left with the connector locked to the inlet without charging for an untold period of time. The exposure to so many charging systems helped OEMs discover such nuances and work to correct them.

Global connections

Harper noted that his group at Argonne helped develop, chair and lead author the SAE J2953 standard for interoperability between EVs and EVSE, so they will update the standard to cover the lessons learned from the Testival. Its results will also help them define international interoperability test procedures. There may even be another testing event with European partners after the launch of a European Interoperability Center this summer, as part of the joint agreement between the DOE and the European Commission. That agreement includes working on vehicle and battery testing procedures, as well as interoperability.

“The governments’ role is to support the national mission to further electrify the vehicle fleet,” said Keith Hardy, Director of ANL’s EV Smart Grid Interoperability Center. “These things need to be standardized between countries and continents to make this work. It’s also become a free-trade issue. You cannot really have free trade if you have different standards, because I can use that as an invisible barrier to trade by just having a different standard.”

Hardy hopes that by the time the European facility opens later in the year, ANL will have a common set of interoperability requirements, and a prototype tool for testing those requirements. “The DC test tool has become an international effort,” he said.

Harper described the test tool as some configuration of a communication controller board, a connector inlet and some type of load or DC source. He built his own test setup using a large Aerovironment ABC-170 dual-channel, high-voltage DC power supply that can emulate a DC fast charger as well as an EV battery. With this setup Harper can test both CCS-enabled PEVs as well as DC fast chargers.

“Interoperability is basically taking two compliant devices and testing them together. If they work, then they’re interoperable,” Harper said. “The worst thing is you can have two compliant devices that are not interoperable. Then you have a really big issue. That means your standard’s bad; there’s gaps in your standard. And just because an EV might be interoperable – it charges with a certain charger – it might not be compliant. You might run into issues down the road where another charger is implemented differently and then it isn’t interoperable. That comes back to where the vehicle wasn’t compliant to begin with, and that’s why we test both interoperability and compliance.”

Perhaps the biggest – and most satisfying – surprise of the Testival was the interoperability of the participant companies, who helped each other when they weren’t required or incentivized to. “A representative from GM said he’d never been to an event where all the manufacturers were so open and so willing to work together,” Harper explained. “In the end, they’re only helping the industry and their companies by working together, and I think that’s something that he’d never been a part of in other areas of the industry. So that was great to see everyone come together and work towards a common goal, share information, share their designs and implementations. That was surprising.”

This article originally appeared in Charged Issue 17 – January/February 2015